Chain Slings Legs

2.0 – GR80 Chain

For the purposes of this Part of EN 818, the following definitions apply:

1. Nominal size: Nominal diameter of the round section steel wire or bar from which the chain is made.

2. Material diameter: Diameter of the material in the chain link as measured.

3. Weld diameter: Diameter at the weld as measured.

4. Length dimensionally affected by welding: Length on either side of the center of the link, affected by welding.

5. Pitch: Internal length of a link as measured.

6. Manufacturing proof force(MPF) of chain: Force to which during manufacture the whole of the chain is subjected.

7. Breaking force( BF): Maximum force which the chain withstands during the course of a static tensile test to destruction.

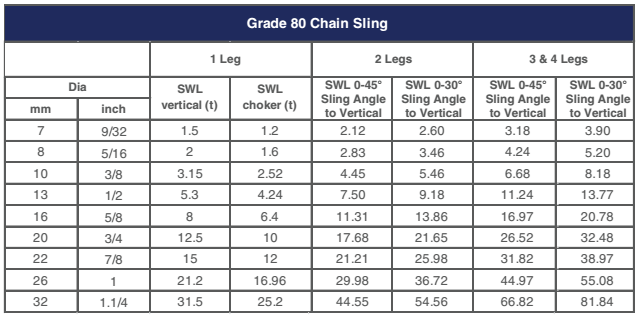

8. Working load limit (WLL) of chain: Maximum mass which the chain hanging vertically is authorized to sustain in general lifting service.

9. Total ultimate elongation (A): Total extension at the point of fracture of the chain expressed as a percentage of the internal length of the test sample.

10. Processing: Any treatment of the chain subsequent to welding, for example, heat treatment, polishing or dimension calibration.

11. Lot: Specified quantity from which test sample(s) is/are selected.

12. Competent person: A designated person, suitably trained qualified by knowledge and practical experience, and with the necessary instructions to enable the required examination to be carried out.

2.1 – Selection of chain slings

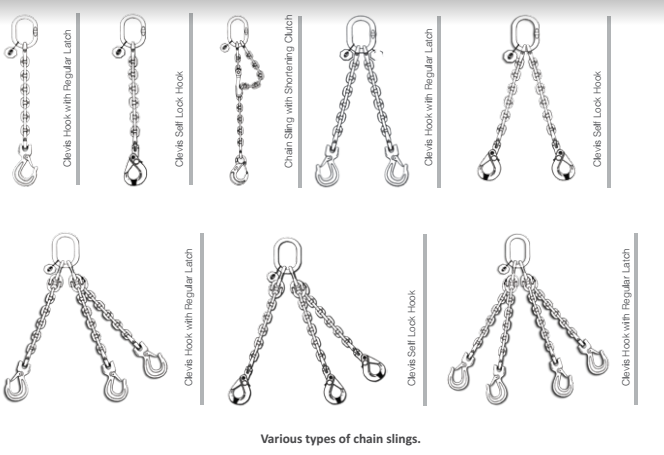

Chain slings are available in a range of material grades, sizes and assemblies. Select the slings to be used and plan the lift taking the following into account:

- Do not attempt lifting operations unless you understand the use of the equipment, the slinging procedures and the mode factors to be applied.

- Do not use defective slings or accessories.

- Do not force, hammer or wedge chain slings or fittings into position; they must fit freely. Check the correct engagement of fittings and appliances.

- Position hooks of multi-leg slings facing outward from the load.

- Do not lift on the point of the hook and ensure that the chain is not twisted or knotted.

- Back hook free legs to the master link to avoid lashing legs which might accidentally become engaged or otherwise become a hazard.

- Take the load steadily and avoid shock loads.

- Do not leave suspended loads unattended. In an emergency cordon off the area.

2.3 – Chain slings manufacturing standards EN 1677