Webbing slings

Type – Double ply polyester webbing sling with reinforced lifting eyes

9.0 – Technical specifications

• Wide & flat load bearing surface

• Sling has reinforced eyes at both ends

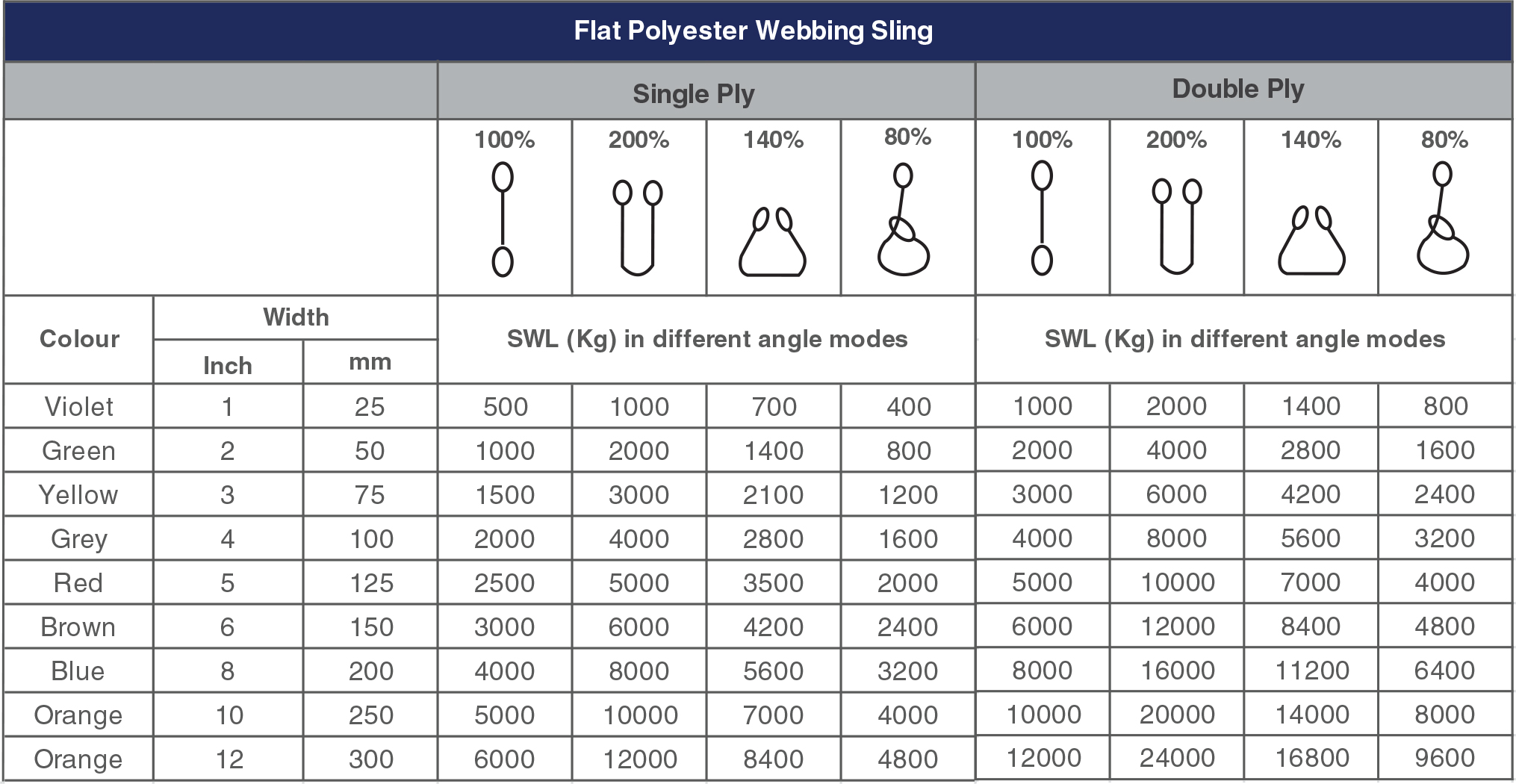

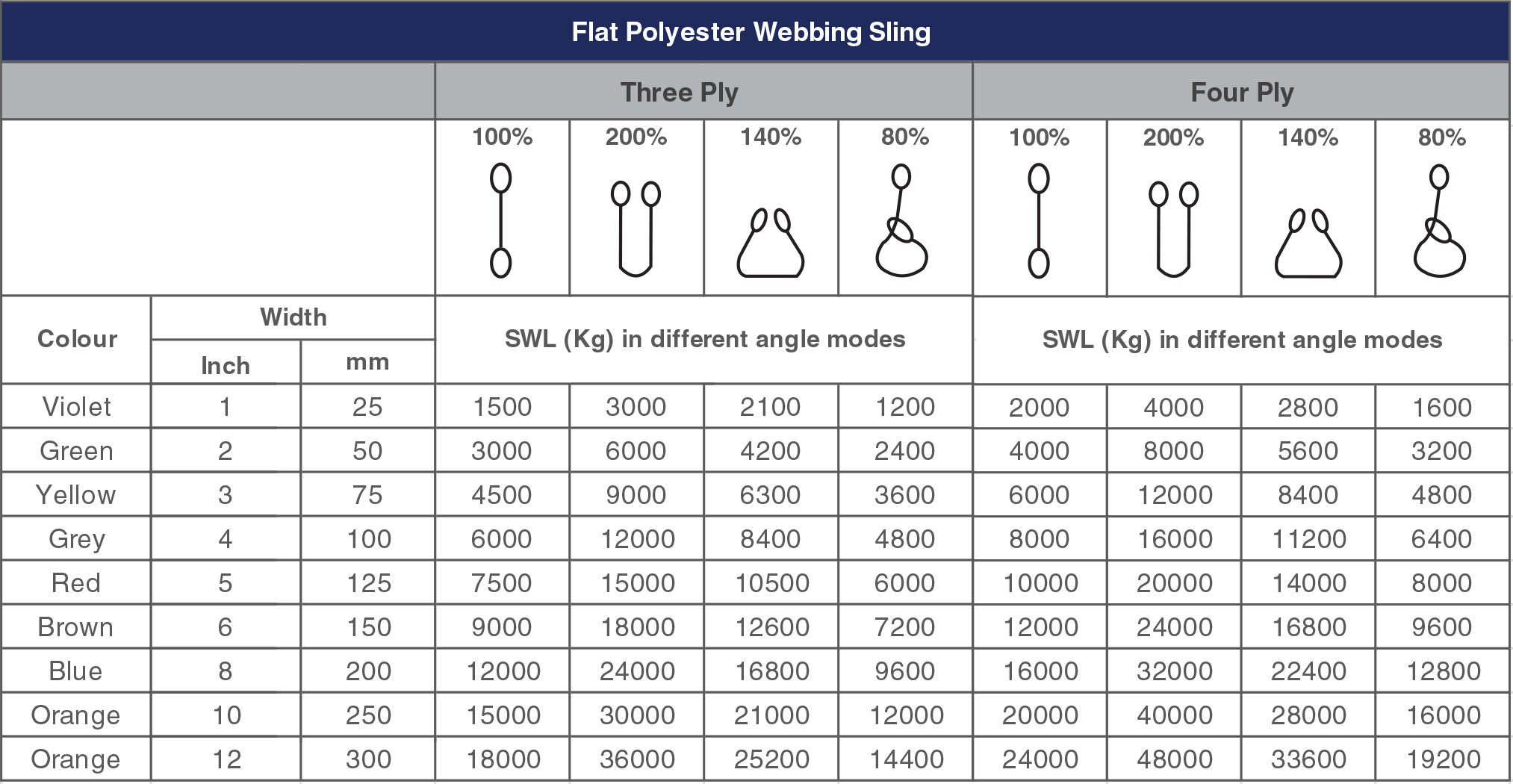

• Capacity from 1t to 12t

• Colour coded according to EN 1492-1.

9.1 – Characteristics

• Low elongation.

9.2 – Norms

• According to Machinery Directive 2006/42/EC & EN 1492-1

• Safety Factor: 7:1 to EN 1492-1

Flat Eye Slings are the most common type of sling. They can be used in all three hitches – Vertical, Choker, and Basket.

In additional to the colour, the number of black lines on these slings indicates its WLL.

Selection of correct Webbing Sling:

Webbing slings are available in a range of materials and sizes in single leg and endless sling forms. Select the slings to

be used and plan the lift taking the following into account:

9.3 – Material

• Polyester identified by a blue label is resistant to moderate strength acids but is damaged by alkalis; polyamide (Nylon)

identified by a green label is virtually immune to alkalis but is damaged by acids; and polypropylene identified by a

brown label is little affected by acids or alkalis but is damaged by some solvents, tars and paints and therefore, suitable

for appliances where the highest resistance to chemicals other then solvents is required.

9.4 – Capacity

The sling must be both long enough and strong enough for the load and the slinging method. Apply the mode factor for

the slinging method. For use at temperatures exceeding 80°C or below 0°C refer to the suppliers instructions. For flat

woven slings made to BS EN 1492-1:2000 + A1: 2008 *Polyester And Polyamide -40ºC to 100º Polypropylene -40ºC to

80ºC Ranges vary in a chemical environment, in which case the advice of the manufacturer or supplier should be sought.

If the slings are used in multi-leg arrangement the angle formed between the legs should not be less than 30° or greater

than 90°. If abrasion, heat generated by friction or cutting from edges or corners are likely select a sling fitted with

protective sleeves and/or use suitable packing. Slings with grade 8 fittings and multi-leg slings with grade 8 master links

should not be used in acidic conditions. Contact with acids or acidic fumes causes hydrogen embrittlement to grade 8

materials. If exposure to chemicals is likely, the manufacturer or supplier should be consulted.