Wire Rope Slings

Dutest maintains a large stock of wire rope for various applications. Our high quality wire ropes are sourced from Europe, Korea, India and UAE. All ropes conform to the relevant International and Local norms and are supplied with Mill Test Certificates.

Features

- Over 1,000 MT stock of superior brand wire ropes

- Brands include DSR, Brunton Wolf, Manho, Kiswire, Bridon

- No minimum order quantity

- Tensile Grades: 1960 N/mm2, 2160 N/mm2, EIPS, EEIPS

- Manufacturing Standards: EN 12385, API 9A, ISO 10425

- Certificates: Mill Test Certificate supplied with all ropes

- Applications: Oil & Gas, Drilling, Marine, Engineering,Cranes & Hoists etc.

Introduction to Wire Rope Slings

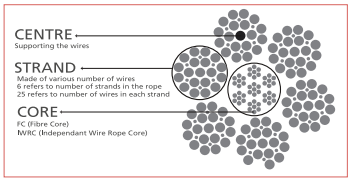

1.0 – Steel Wire Rope

General information on wire ropes

Wire rope is made of plaiting strands of wire – normally medium carbon steel – into a thick cable. The strands are formed around a core. The strands in wire ropes are made of wore twisted together. Strands with smaller diameter wires are less abrasion resistant and more fatigue resistant. Strands made with thicker length of wore are more abrasion resistant and less fatigue resistant.

Sizes : From 3mm to 80mm

Surface Finish : Galvanized and Ungalvanized

Core : IWRC, FC and WSC

Typical Wire Constructions : 6×36, 6X19, 18×7 and more

Tensile Strengths : 1960 N/mm2 (EIPS) and 2160 N/mm2 (EEIPS)

Lay of wire rope

The lay of a wire rope describes the manner in which either the wires in a strand, or the strands in the rope, are laid in a helix.

Left and right hand lay

Left hand lay or right hand lay describe the manner in which the strands are laid to form the rope. To determine the lay of strands in the rope, a viewer looks at the rope as it points away from them. If the strands appear to turn in a clockwise direction, or like a right-hand thread, as the strands progress away from the viewer, the rope has a right hand lay. The

picture of steel wire rope on this page shows a rope with right hand lay. If the strands appear to turn in an anti-clockwise direction, or like a left-hand thread, as the strands progress away from the viewer, the rope has a left hand lay.

Ordinary, lang’s and alternate lay

Ordinary and Lang’s lay describe the manner in which the wires are laid to form a strand of the wire rope. To determine which has been used first identify if left or right hand lay has been used to make the rope. Then identify if a right or left hand lay has been used to twist the wires in each strand.

Ordinary lay The lay of wires in each strand is in the opposite direction to the lay of the strands that form the wire.

Lang’s lay The lay of wires in each strand is in the same direction as the lay of the strands that form the wire.

Alternate lay The lay of wires in the strands alternate around the rope between being in the opposite and same direction to the lay of the strands that form the wire rope.

Regular lay Alternate term for ordinary lay.

Albert’s lay Archaic term for Lang’s lay.

Reverse lay Alternate term for alternate lay.

Spring lay This is not a term used to classify a lay as defined in this section. It refers to a specific construction type of wire rope.